Polyurethane Foaming

Integration of functions - Lightness - Technicality

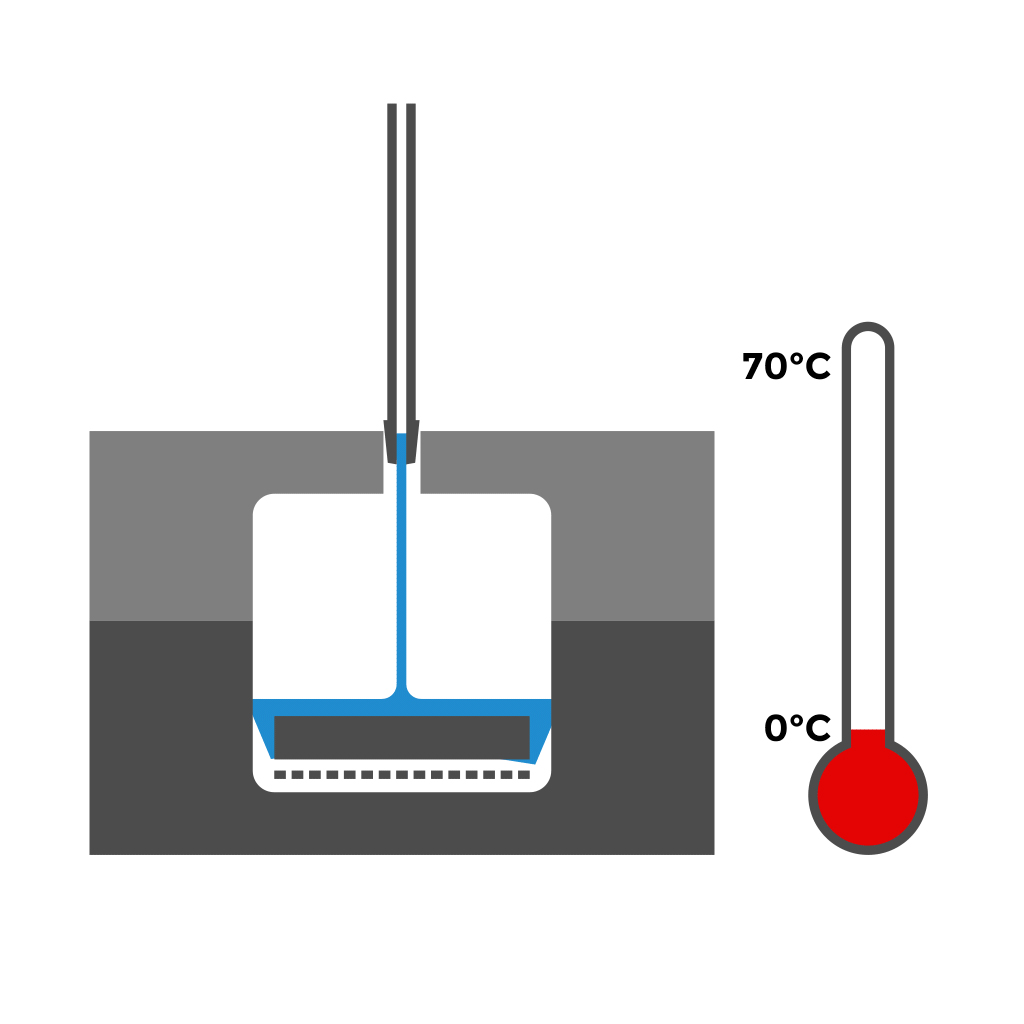

The polyurethane foaming is a process that allows the production of flexible or rigid foam parts by casting a bi-component mixture in a mold.

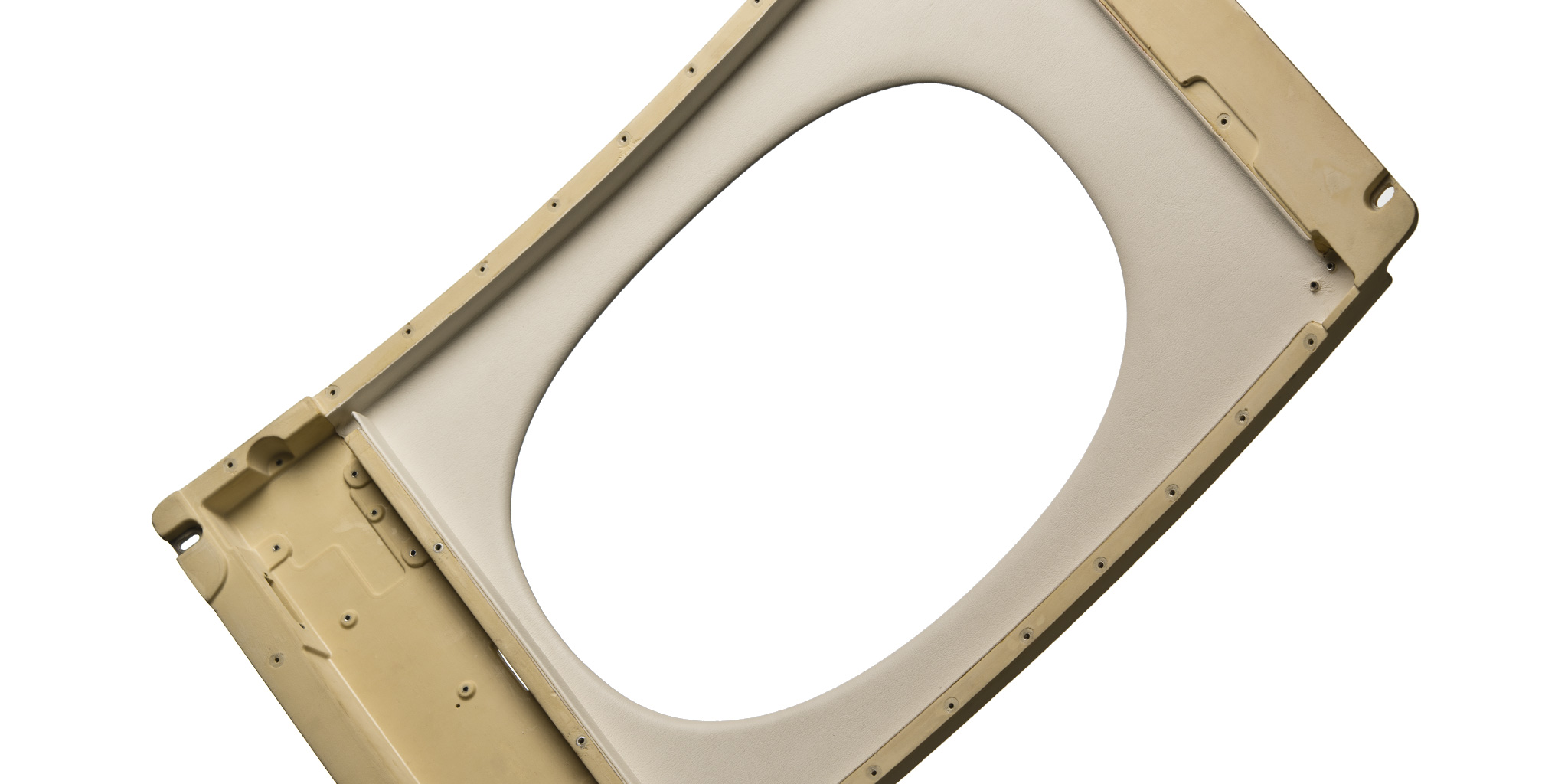

Rigid polyurethane foam is used to make structural parts.

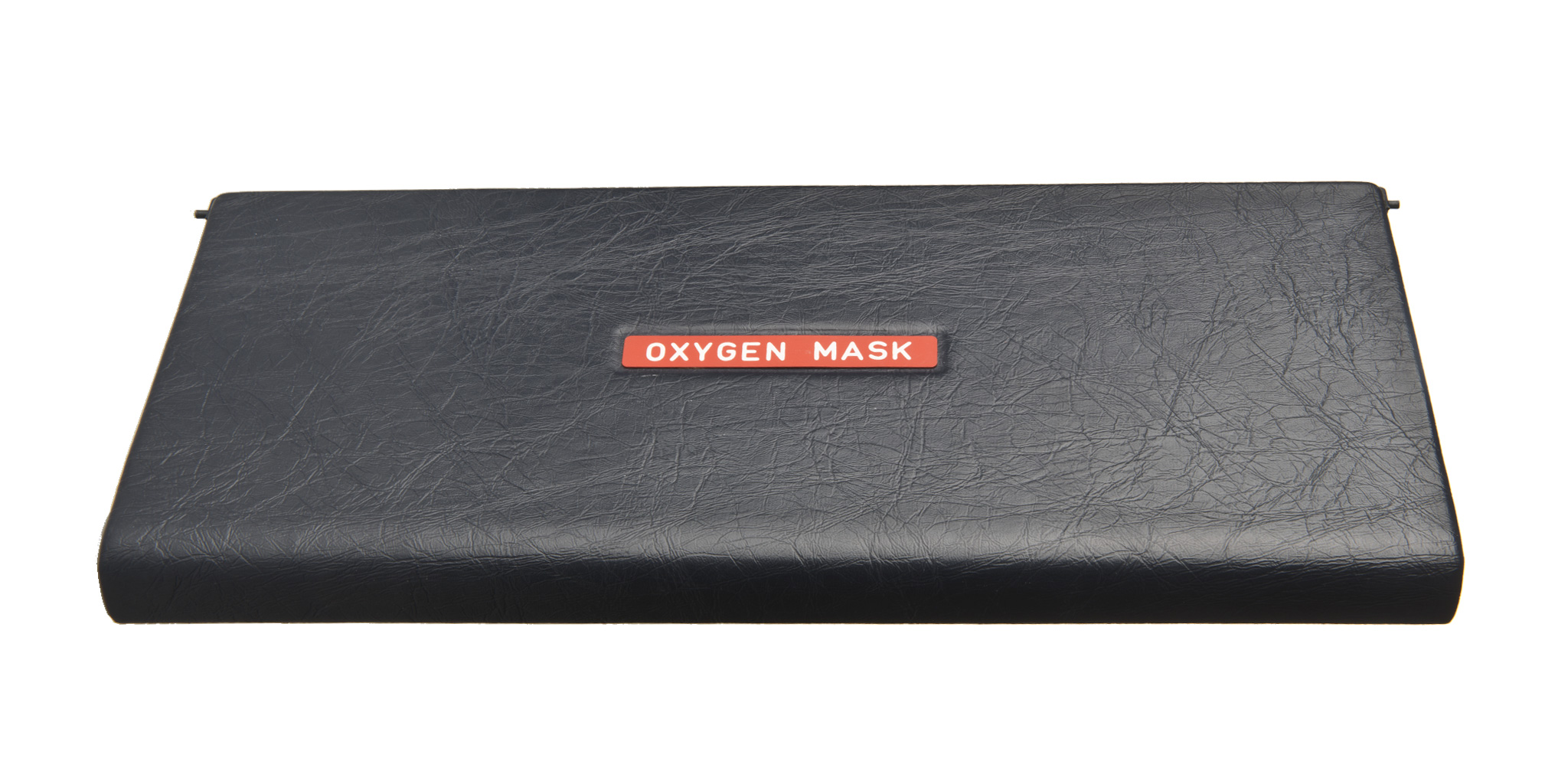

Flexible polyurethane foam is used to make technical trimmings with a specific surface finish.

The part can have a given granularity aspect, can be covered with fabric or leather or can even be painted. It is also possible to embed inserts in the foam to realize specific functions or integrate stiffeners to obtain mechanical strength.

We develop our polyurethane foam to better meet your needs, and we are experts in fireproofing.